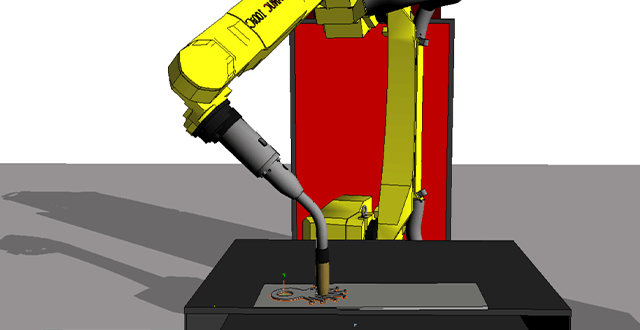

Optimize production with seamless robot programming

OCTOPUZ provides a virtual offline environment that perfectly matches your real-world cell and enables tasks like training, programming, and integration to be done with minimal disruption to production. The time it takes to adopt new programs can be cut down from weeks to a single day, enabling the robotization of short-run production.