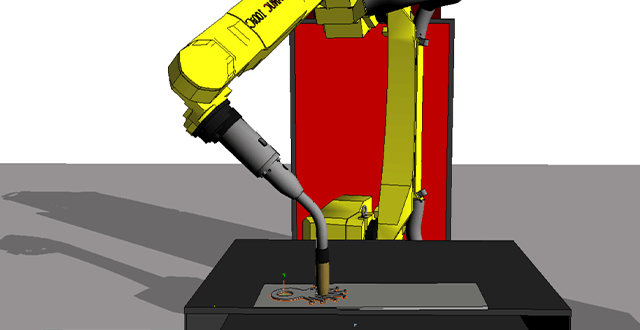

Collaborate to deliver cutting-edge robot solutions

Partners and OEMs are constantly innovating, and OCTOPUZ helps facilitate the development and delivery of next-gen robotic solutions. By offering flexible, powerful offline programming tools, OCTOPUZ empowers OEMs to collaborate with their customers, simulate workflows, and ensure that robots are ready to perform optimally right out of the box. This reduces deployment risks and enhances the quality of the solutions you provide.